Ellwood Group

Download PDF

- Increased Visibility and Standardization of Data

- IT Staff Can Support the System Company-Wide

- Elimination of Customizations

- Increased Productivity

About Ellwood Group

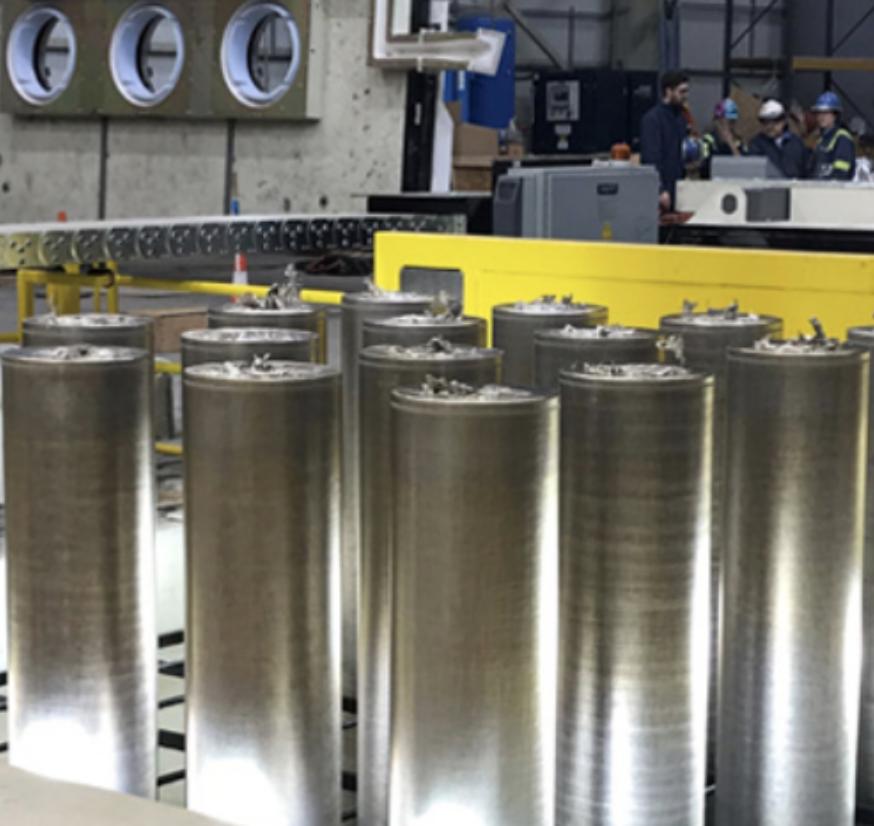

With over 2,100 employees and more than 25 companies in the steelmaking, iron castings, and forgings industries, Ellwood Group is a major supplier of high-quality, engineered, heavy metal components to customers worldwide. The 110-year-old company is family-owned and recognized for its dedication to quality and technology.

Ellwood’s commitment to quality and advanced technology has allowed the company to grow and thrive in an industry where, in recent years, more companies have exited the market than entered. The company’s strong diversification into markets outside of the oil and gas industry—historically a key customer base—has enabled continued growth despite market volatility.

Ellwood’s investment in technology extends beyond production equipment and facilities to include robust business systems that provide employees with a true competitive advantage.

In 1992, Ellwood first implemented Infor CloudSuite Industrial (SyteLine) ERP to manage business operations at its Ellwood Engineered Castings facility in Hubbard, OH. Today, the entire organization utilizes the system. Rich Owrey, vice president of information technology at Ellwood, explains that as the company expanded, new installations of the system were implemented separately at each new location. Now, Ellwood is leveraging newer technology and is in the process of consolidating these separate installations into a unified system.

The system consolidation effort provides several benefits, including increased visibility and standardization of data throughout the organization. Mr. Owrey also sees this project as an opportunity to upgrade sites to the latest version of CloudSuite Industrial while re-evaluating system usage and eliminating customizations that may no longer be needed.

“CloudSuite Industrial has always provided us with a good framework that makes customization and integration relatively easy when needed,” said Mr. Owrey. “This allows my IT staff of only 19 to support and maintain the system across the entire Ellwood organization. And the new version of CloudSuite Industrial provides us with even more advanced capabilities that will allow our users to access and analyze data on their own, without the need for my staff to assist.”

Mr. Owrey points specifically to the in-system data query capabilities, the enhanced integrations with office productivity tools, and the ability to personalize the system without the need for a developer. At sites where the new version of CloudSuite Industrial has been implemented, users are seeing significant productivity gains.

Ellwood is looking forward to completing its CloudSuite Industrial ERP consolidation project and fully standardizing the system across the organization. Currently, Ellwood uses almost every module within the CloudSuite Industrial system, as well as Infor’s Quality Control System and the Infor Dynamic Enterprise Performance Management (d/EPM) system, which allows Ellwood’s management team to view, manage, and analyze consolidated financial data.